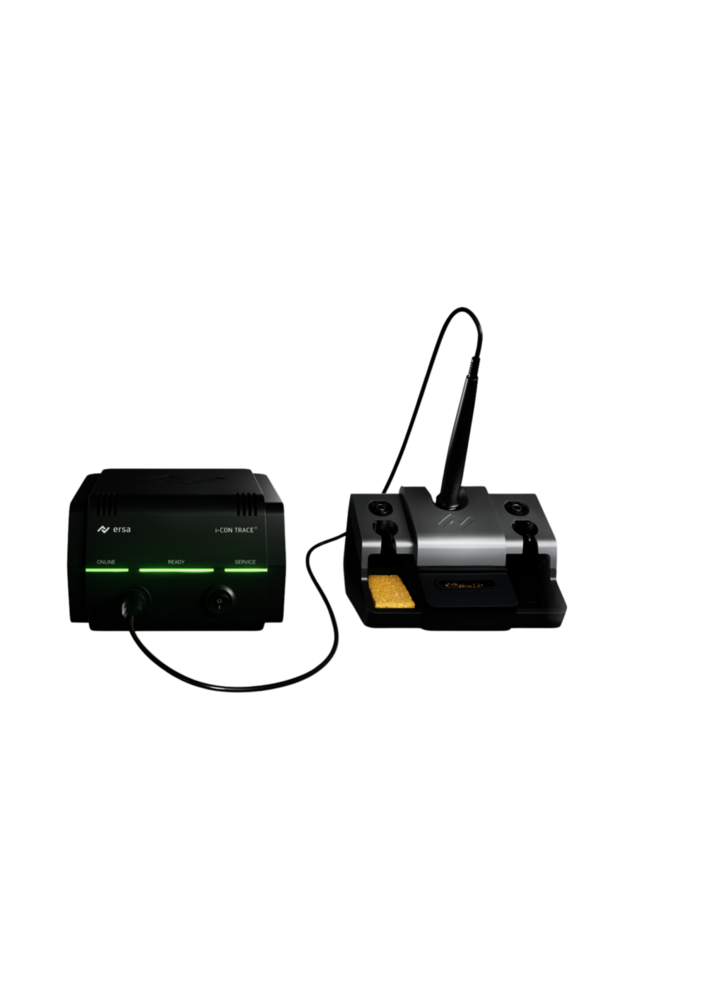

About ERSA SOLDERING STATION

Complete traceability for hand soldering!

The i-CON TRACE is the worlds first fully networkable soldering station. With integrated WLAN, Bluetooth and network card, the system can be fully integrated into MES-controlled production processes, making the complete hand soldering process traceable and documentable.

Highlights i-CON TRACE

- Ersa IOT Soldering Station Increase process reliability by presetting the parameters and documenting the process data.

- Increased productivity and soldering quality thanks to particularly fast and safe Tip'n'Turn soldering tip changesHighest precision and excellent reliability

- Significant cost savings thanks to separately replaceable soldering tips

Technical Specification:

- Dimensions (W x D x H) in mm:156 x 175 x 102

- Weight in kg:3.1

- Antistatic version (y/n):j

- Rated power in W:150

- Power consumption standby in W:

- Nominal voltage in V AC:220 - 240

- Secondary voltage in V:24

- Temperature range in C:50 - 450

- Digital display (y/n):n

- Communication:WLAN, LAN

Precision and Safety with Digital LED ControlAchieve consistent and precise soldering results using the integrated Digital LED display and dial knob temperature control. With ESD-safe construction and overheat protection, the station safeguards both the operator and sensitive electronic components. The insulated handle further enhances user safety, making it ideal for detailed and extended soldering sessions.

Efficient Setup with User-Friendly FeaturesThe ERSA Soldering Station simplifies professional workflow with its ergonomic handle, quick <60s warm-up, and sturdy bench-top mounting. An included stand and cleaning sponge help maintain the tip's cleanliness for improved efficiency, while the smooth, durable finish ensures easy maintenance and lasting durability.

FAQ's of ERSA SOLDERING STATION:

Q: How do I set the desired operating temperature on the ERSA Soldering Station?

A: You can set the operating temperature using the dial knob temperature control located on the front panel. The selected temperature is clearly displayed on the Digital LED screen for precise adjustments.

Q: What types of soldering tasks can I perform with this station?

A: The station is designed for both soldering and desoldering of electronic components. Its interchangeable tips cater to various tasks, from delicate circuit work to more robust electronic assembly jobs.

Q: When should the cleaning sponge be used during operation?

A: Use the provided cleaning sponge regularly during and after soldering sessions to remove oxidation and solder residue from the tip. This maintains optimal heat transfer and prolongs tip life.

Q: Where is the ERSA Soldering Station typically installed and used?

A: Designed for bench-top mounting, the station is best used in workspaces like electronics labs, repair shops, or manufacturing facilities. Its standard length and three-pin socket fit most workbench setups.

Q: What is the process for replacing the soldering tip?

A: To replace the tip, first allow the station to cool. Unscrew the secure holder, gently remove the old tip, insert your chosen compatible tip, and re-secure. Always ensure the power is off when changing the tip.

Q: How does the overheat protection feature benefit the user?

A: The overheat protection ensures that the station automatically prevents excessive temperature rise, safeguarding both the user and sensitive components from heat-related damage during prolonged use.

Q: What are the main benefits of the ergonomic handle and insulated design?

A: The ergonomic handle reduces user fatigue during extended projects, while the insulated design protects your hand from heat, enhancing comfort and safety throughout your soldering tasks.